close

Choose Your Site

Global

| Availability: | |

|---|---|

| Quantity: | |

Model | MW8-2030GT |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-2500g Depend the product |

Speed | 10-60bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1% according product |

Total Power | 3.5Kw |

Air Requirement | 0.6m3/min 0.8mpa |

Dimension | 4600*2500*4000mm |

Weight | 2000kgs |

Product Usage

The bag-type packaging machine is mainly used for automatic packaging of granules, powder, block, liquid, soft cans, toys, hardware and other products. According to different materials, match different measuring equipment. The packaging material has low loss, accurate weight, and good sealing quality. The prefabricated packaging bag is used, and the packaging bag has a beautiful pattern, which improves the product grade. Bag feeding is suitable for packaging materials such as paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE composite.

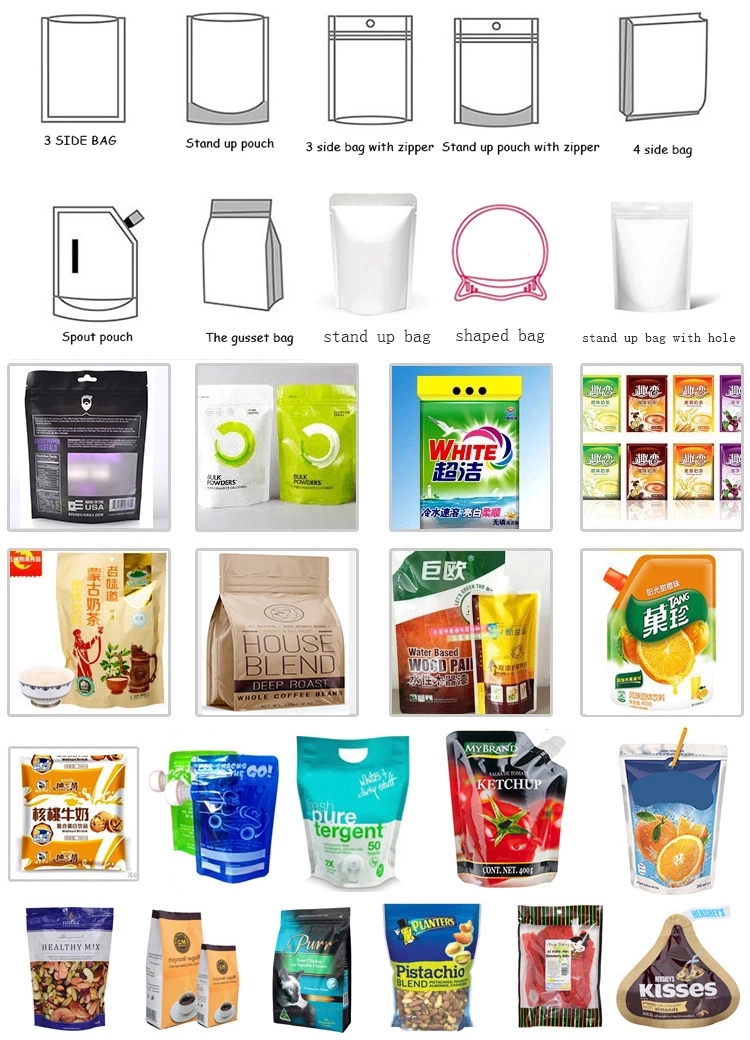

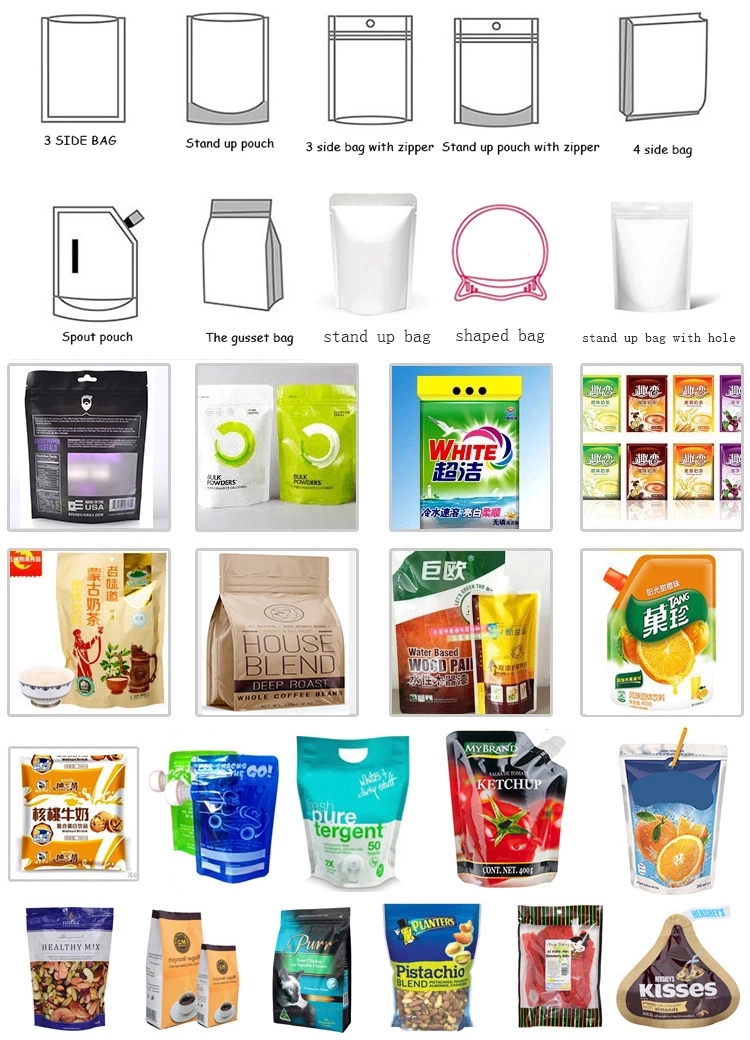

Pouch Type

Stand Bag, Handle Bag, Zipper Bag, Four Side Sealing Bag, Paper Bag, Compound bag etc.

Feature

The advanced mechanical transmission mechanism of the bag packaging machine can ensure stable operation, strong compatibility of sizes and specifications, stable heat sealing structure and excellent sealing quality.

1. Bag-feeding packaging machine is suitable for large packaging bags, automatic metering filling and sealing.

2. The advanced bagging mechanism of the bag packaging machine ensures a high bagging rate.

3. The advanced design concept of the bag-type packaging machine ensures the stability of the equipment operation, reduces the defective rate and prolongs the service life of the equipment.

4. Use high-quality accessories for the bag packaging machine to ensure the durability and stability of the machine.

5. Pre-made packaging bags are used for the bag packaging machine. The packaging picture is perfect, the vacuum is high, and the sealing quality is good, which greatly improves the product quality and grade.

6. The advanced PLC plus POD electric press system is used for the bag packaging machine. The man-machine interface is friendly and easy to operate.

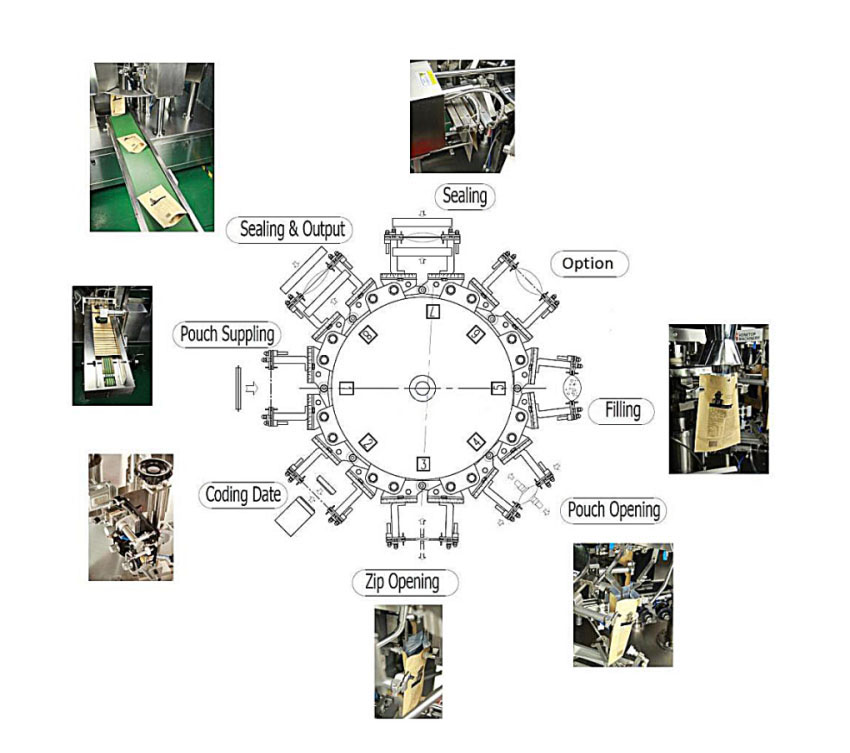

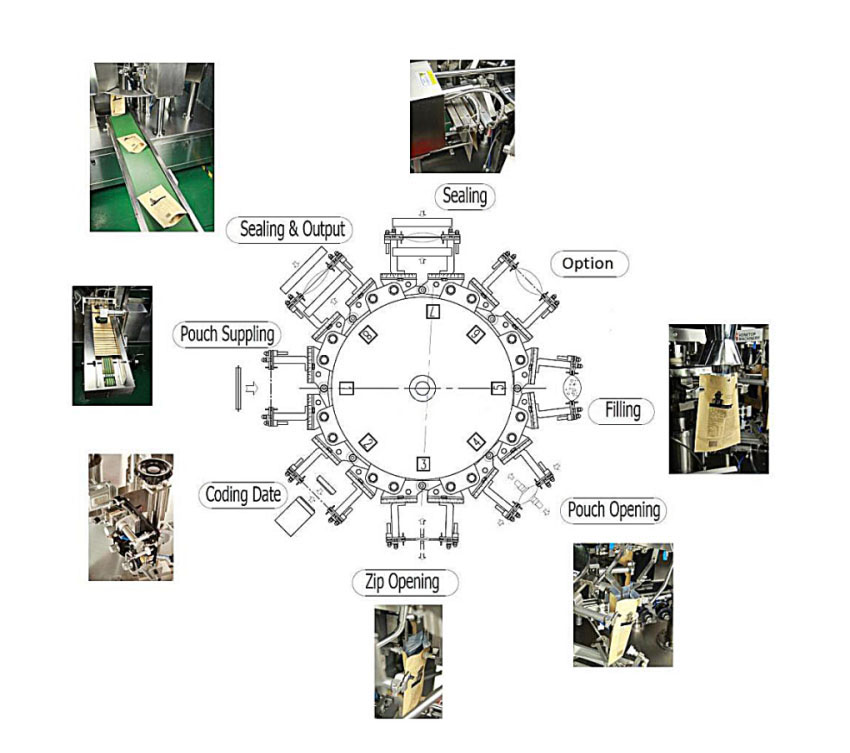

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output

Model | MW8-2030GT |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-2500g Depend the product |

Speed | 10-60bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1% according product |

Total Power | 3.5Kw |

Air Requirement | 0.6m3/min 0.8mpa |

Dimension | 4600*2500*4000mm |

Weight | 2000kgs |

Product Usage

The bag-type packaging machine is mainly used for automatic packaging of granules, powder, block, liquid, soft cans, toys, hardware and other products. According to different materials, match different measuring equipment. The packaging material has low loss, accurate weight, and good sealing quality. The prefabricated packaging bag is used, and the packaging bag has a beautiful pattern, which improves the product grade. Bag feeding is suitable for packaging materials such as paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE composite.

Pouch Type

Stand Bag, Handle Bag, Zipper Bag, Four Side Sealing Bag, Paper Bag, Compound bag etc.

Feature

The advanced mechanical transmission mechanism of the bag packaging machine can ensure stable operation, strong compatibility of sizes and specifications, stable heat sealing structure and excellent sealing quality.

1. Bag-feeding packaging machine is suitable for large packaging bags, automatic metering filling and sealing.

2. The advanced bagging mechanism of the bag packaging machine ensures a high bagging rate.

3. The advanced design concept of the bag-type packaging machine ensures the stability of the equipment operation, reduces the defective rate and prolongs the service life of the equipment.

4. Use high-quality accessories for the bag packaging machine to ensure the durability and stability of the machine.

5. Pre-made packaging bags are used for the bag packaging machine. The packaging picture is perfect, the vacuum is high, and the sealing quality is good, which greatly improves the product quality and grade.

6. The advanced PLC plus POD electric press system is used for the bag packaging machine. The man-machine interface is friendly and easy to operate.

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output