close

Choose Your Site

Global

| Availability: | |

|---|---|

Model | MW8-2030YT |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-1500ml Depend the product |

Speed | 10-50bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1% according product |

Total Power | 2.6Kw |

Voltage | 380V 3Phase 50HZ |

Dimension | 1460*2500*1400mm |

Weight | 1450KGS |

Product Application:

The machine is used for packing peanut butter, jam, chili sauce, tomato sauce, bean paste, detergent, rice wine, rice vinegar, juice etc.

Pouch Type:

Stand Bag , Handle Bag , Zipper Bag , Four Side Sealing Bag , Three Side Sealing Bag , Paper Bag , Compound bag etc,

The premade pouch packaging machine is easy to operate and adopts an advanced mechanical transmission system to realize automatic bag taking, automatic weighing, automatic loading, automatic vacuuming, automatic sealing and automatic unloading.

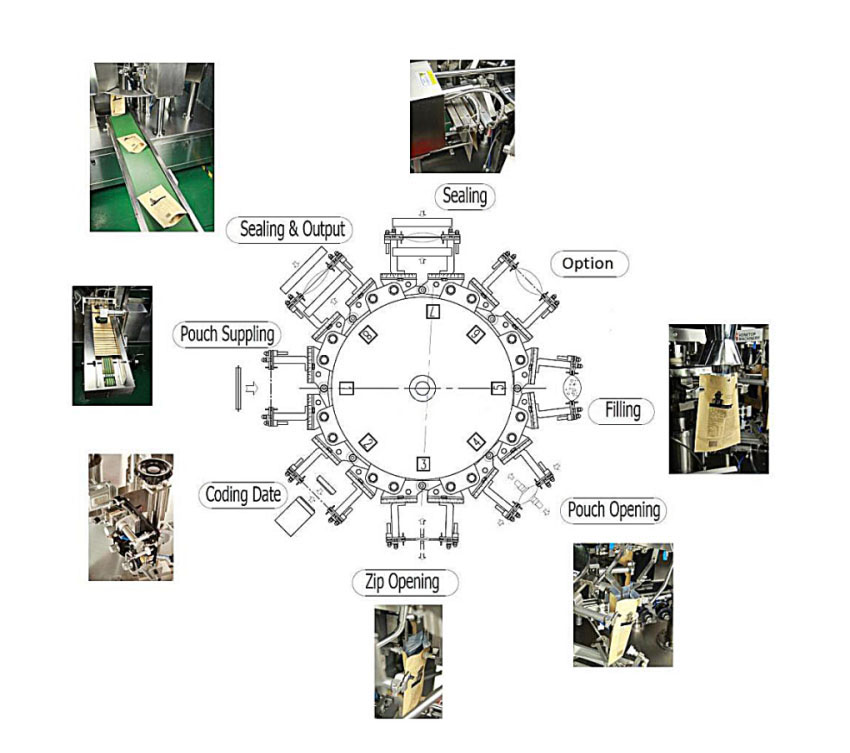

Machine Process drawing: (8 working stations for reference):

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output

Model | MW8-2030YT |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-1500ml Depend the product |

Speed | 10-50bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1% according product |

Total Power | 2.6Kw |

Voltage | 380V 3Phase 50HZ |

Dimension | 1460*2500*1400mm |

Weight | 1450KGS |

Product Application:

The machine is used for packing peanut butter, jam, chili sauce, tomato sauce, bean paste, detergent, rice wine, rice vinegar, juice etc.

Pouch Type:

Stand Bag , Handle Bag , Zipper Bag , Four Side Sealing Bag , Three Side Sealing Bag , Paper Bag , Compound bag etc,

The premade pouch packaging machine is easy to operate and adopts an advanced mechanical transmission system to realize automatic bag taking, automatic weighing, automatic loading, automatic vacuuming, automatic sealing and automatic unloading.

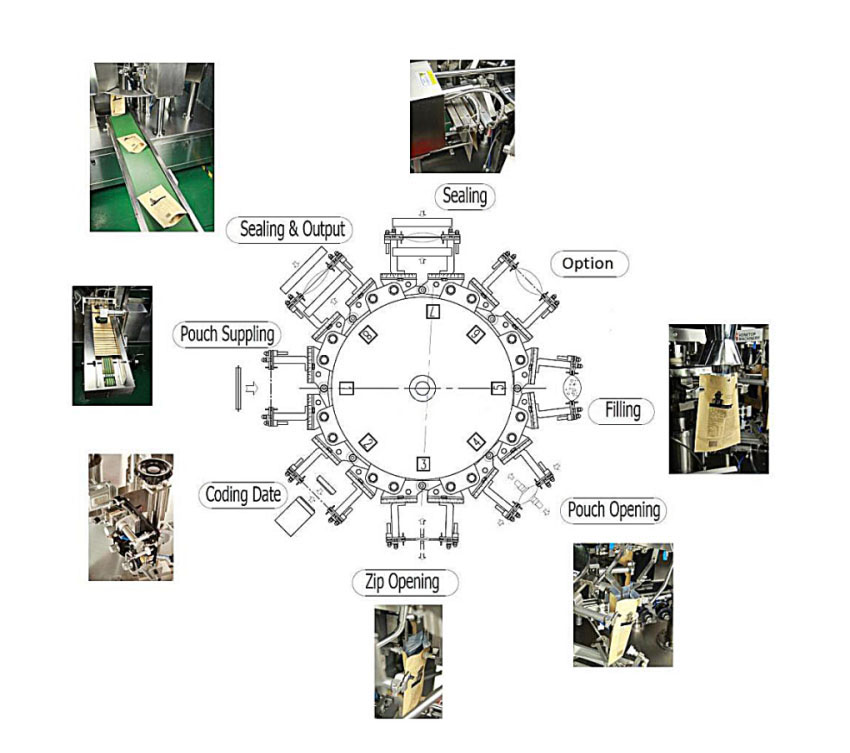

Machine Process drawing: (8 working stations for reference):

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output