close

Choose Your Site

Global

| Availability: | |

|---|---|

| Quantity: | |

Model | MW8-2030FM |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-1500g Depend the product |

Speed | 10-60bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1-2g According the product |

Total Power | 3.6Kw |

Dimension | 1350*3900*2400mm |

Weight | 1700KGS |

Air Requirement | 0.6m3/min |

Product Usage

Scope of application: Suitable for packaging those powders and small granular materials that are easy to flow or have poor fluidity, such as milk powder, protein powder, cocoa powder, additives, powders, small granule drugs, veterinary drugs, glucose, condiments, solid drinks, carbon Powder, talcum powder, pesticides, etc. The appearance of the whole machine is made of stainless steel except for the motor; the combined transparent material box can be easily removed and washed without tools. It is not easy to wear, accurate positioning, speed can be set, stable performance and other advantages. Using PLC control, it has the advantages of stable operation, anti-interference, high weighing accuracy and so on. The touch screen in Chinese and English clearly displays the working status, operation instructions, fault status and production statistics, etc. The operation is simple and intuitive. Various product adjustment parameter formulas can be stored for later use, and up to 7 formulas can be stored.

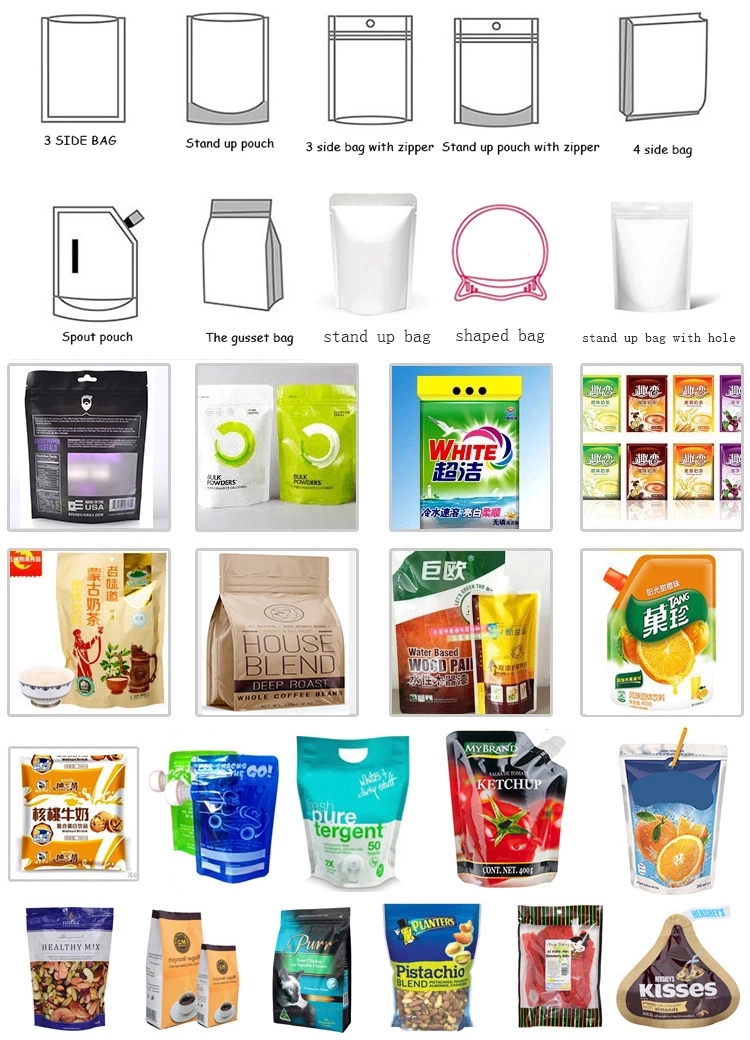

Pouch Type

Stand Bag, Handle Bag, Zipper Bag, Four Side Sealing Bag, Paper Bag, Compound bag etc.

Feature

1. The fully automatic food powder packaging machine is easy to operate, adopts German Siemens PLC control, and is equipped with a touch screen man-machine interface control system.

2. Frequency conversion speed regulation: This machine adopts frequency conversion speed regulation device, and the speed can be adjusted at will within the specified range.

3. Automatic detection: if the bag is not opened or the bag is incomplete, no material is added, no heat sealing, the bag can be used again, no material is wasted, and the production cost is saved for the user.

4. Safety device: it will prompt when the working air pressure is abnormal or the heating tube is faulty.

5. The bag width is adjusted by motor control, and then equipped with a machine glass safety door, some imported engineering plastic bearings, no need to add oil, to reduce the pollution of materials; the use of oil-free vacuum pump to avoid pollution of the production environment.

6. Low loss of packaging materials: the machine uses pre-made packaging bags, which have beautiful patterns and good sealing quality, thus improving the product quality. It meets the hygienic standards of the food processing industry. The parts on the machine that are in contact with the materials or packaging bags are processed with stainless steel or other materials that meet the food hygiene requirements, ensuring a wide range of food hygiene and safe packaging.

7. Wide range of packaging materials: by choosing different meters, it can be suitable for packaging of liquids, sauces, granules, powders, irregular lumps and other materials.

8. Wide range of packaging bags: prefabricated bags and paper bags made of multi-layer composite film, single-layer PE, PP and other materials can be applied.

9. The use of dual motors: feeding motor and vibration motor, each independently controlled. The material box is vibrated and the amplitude is adjustable. The material box is designed as a separate type, which is easy to load and unload. Vibration motor reinforcement. In order to facilitate the cleaning of the residual material, the spiral can be reversed and discharged, the gate of the material tube has a gate to discharge, and the entire spiral can be easily taken out.

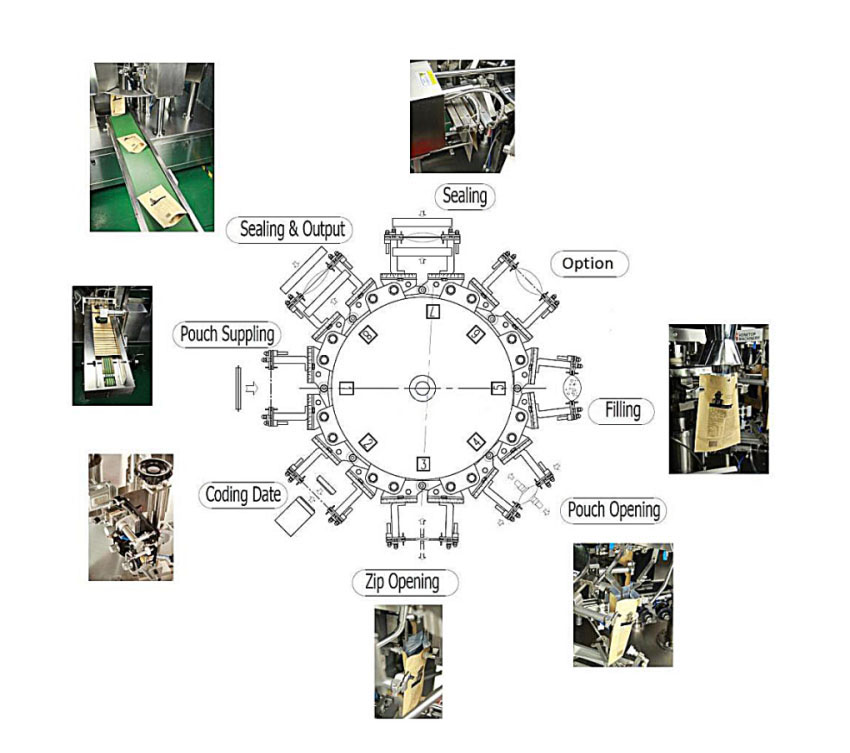

Machine Process drawing: (8 working stations for reference)

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output

Model | MW8-2030FM |

Bag Size | Width:80~200mm , Length :100-300mm |

Fill Weight | 10-1500g Depend the product |

Speed | 10-60bags /min , The Speed is up to product and weight |

Filling accuracy | ≤±1-2g According the product |

Total Power | 3.6Kw |

Dimension | 1350*3900*2400mm |

Weight | 1700KGS |

Air Requirement | 0.6m3/min |

Product Usage

Scope of application: Suitable for packaging those powders and small granular materials that are easy to flow or have poor fluidity, such as milk powder, protein powder, cocoa powder, additives, powders, small granule drugs, veterinary drugs, glucose, condiments, solid drinks, carbon Powder, talcum powder, pesticides, etc. The appearance of the whole machine is made of stainless steel except for the motor; the combined transparent material box can be easily removed and washed without tools. It is not easy to wear, accurate positioning, speed can be set, stable performance and other advantages. Using PLC control, it has the advantages of stable operation, anti-interference, high weighing accuracy and so on. The touch screen in Chinese and English clearly displays the working status, operation instructions, fault status and production statistics, etc. The operation is simple and intuitive. Various product adjustment parameter formulas can be stored for later use, and up to 7 formulas can be stored.

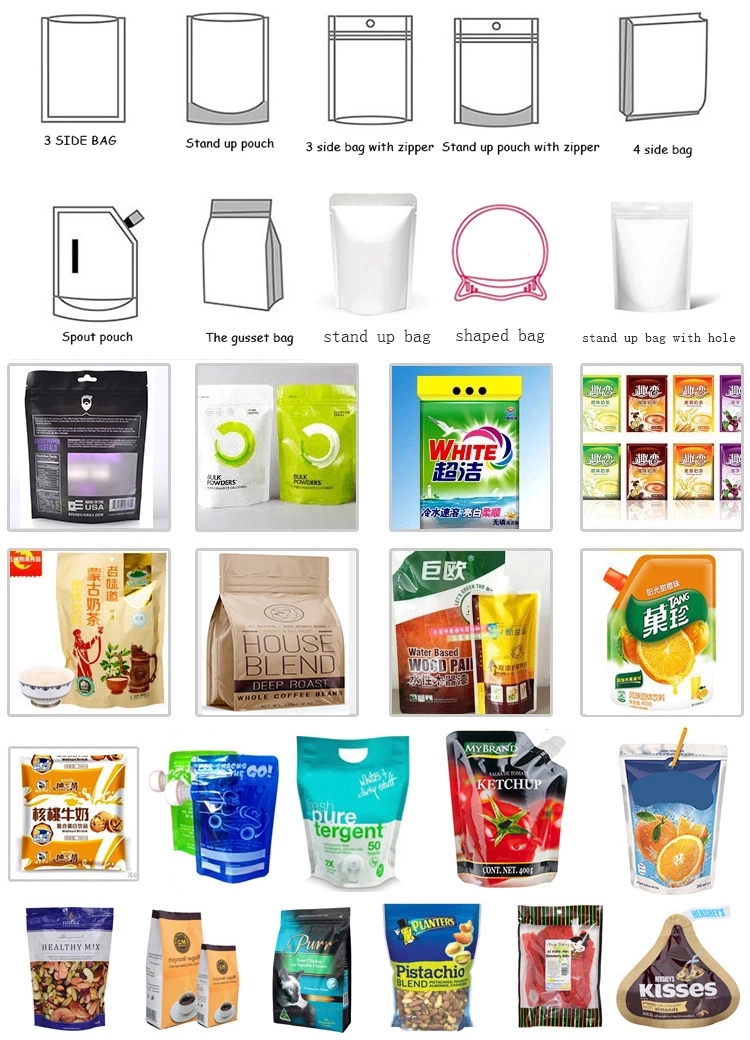

Pouch Type

Stand Bag, Handle Bag, Zipper Bag, Four Side Sealing Bag, Paper Bag, Compound bag etc.

Feature

1. The fully automatic food powder packaging machine is easy to operate, adopts German Siemens PLC control, and is equipped with a touch screen man-machine interface control system.

2. Frequency conversion speed regulation: This machine adopts frequency conversion speed regulation device, and the speed can be adjusted at will within the specified range.

3. Automatic detection: if the bag is not opened or the bag is incomplete, no material is added, no heat sealing, the bag can be used again, no material is wasted, and the production cost is saved for the user.

4. Safety device: it will prompt when the working air pressure is abnormal or the heating tube is faulty.

5. The bag width is adjusted by motor control, and then equipped with a machine glass safety door, some imported engineering plastic bearings, no need to add oil, to reduce the pollution of materials; the use of oil-free vacuum pump to avoid pollution of the production environment.

6. Low loss of packaging materials: the machine uses pre-made packaging bags, which have beautiful patterns and good sealing quality, thus improving the product quality. It meets the hygienic standards of the food processing industry. The parts on the machine that are in contact with the materials or packaging bags are processed with stainless steel or other materials that meet the food hygiene requirements, ensuring a wide range of food hygiene and safe packaging.

7. Wide range of packaging materials: by choosing different meters, it can be suitable for packaging of liquids, sauces, granules, powders, irregular lumps and other materials.

8. Wide range of packaging bags: prefabricated bags and paper bags made of multi-layer composite film, single-layer PE, PP and other materials can be applied.

9. The use of dual motors: feeding motor and vibration motor, each independently controlled. The material box is vibrated and the amplitude is adjustable. The material box is designed as a separate type, which is easy to load and unload. Vibration motor reinforcement. In order to facilitate the cleaning of the residual material, the spiral can be reversed and discharged, the gate of the material tube has a gate to discharge, and the entire spiral can be easily taken out.

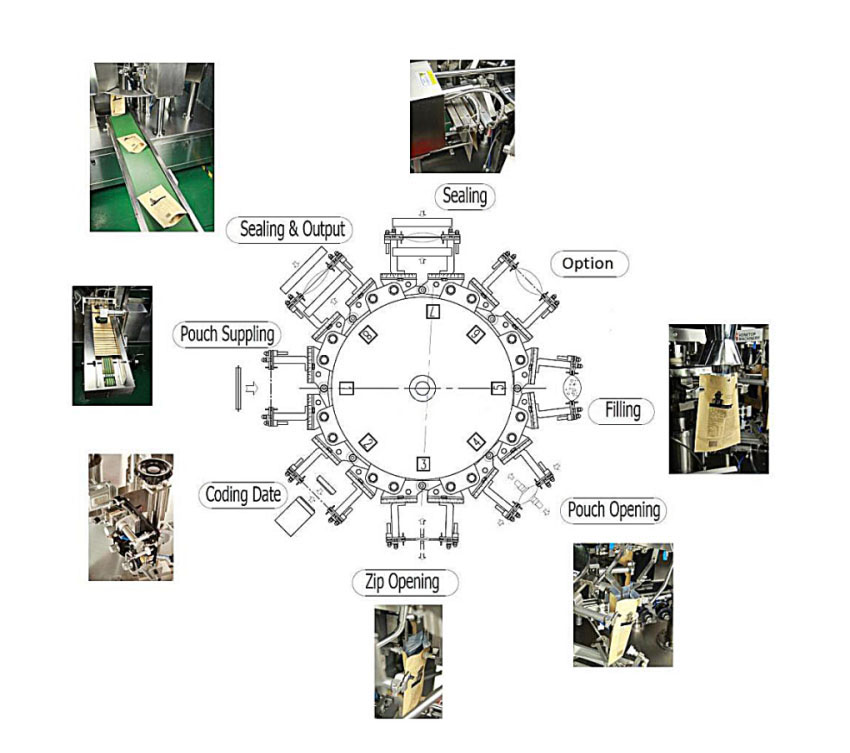

Machine Process drawing: (8 working stations for reference)

1. Pouch Supplying --> 2. Coding Date + --> 3. Zip Opening (if need)--> 4. Pouch Opening ---> 5. Filling + Vibrating (if need)---> 6. Option functions (Nitrogen flushing/2nd fillings ) --> 7. Sealing 1st ---> 8. Sealing 2nd + Output