close

Choose Your Site

Global

| Availability: | |

|---|---|

Usage

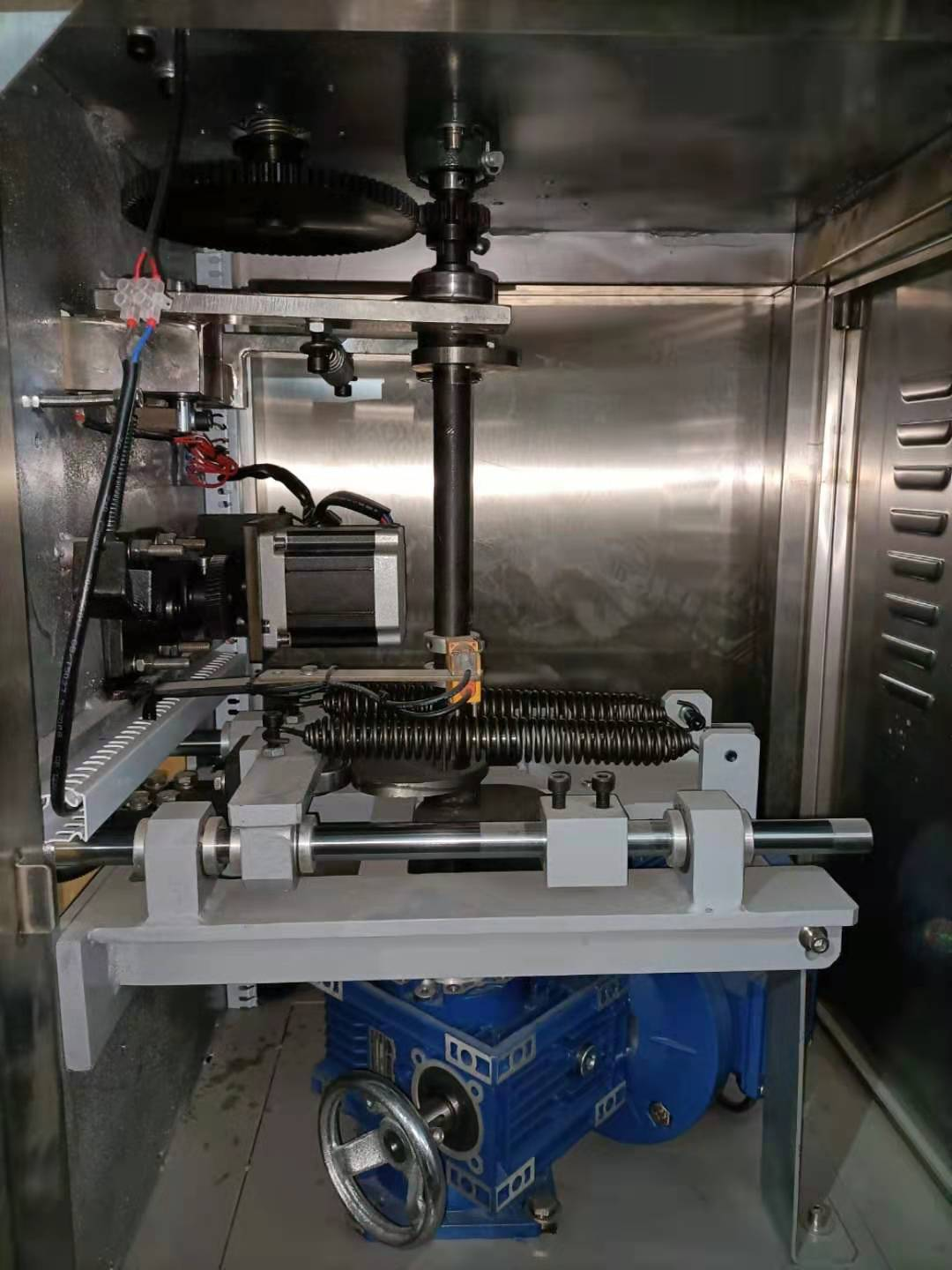

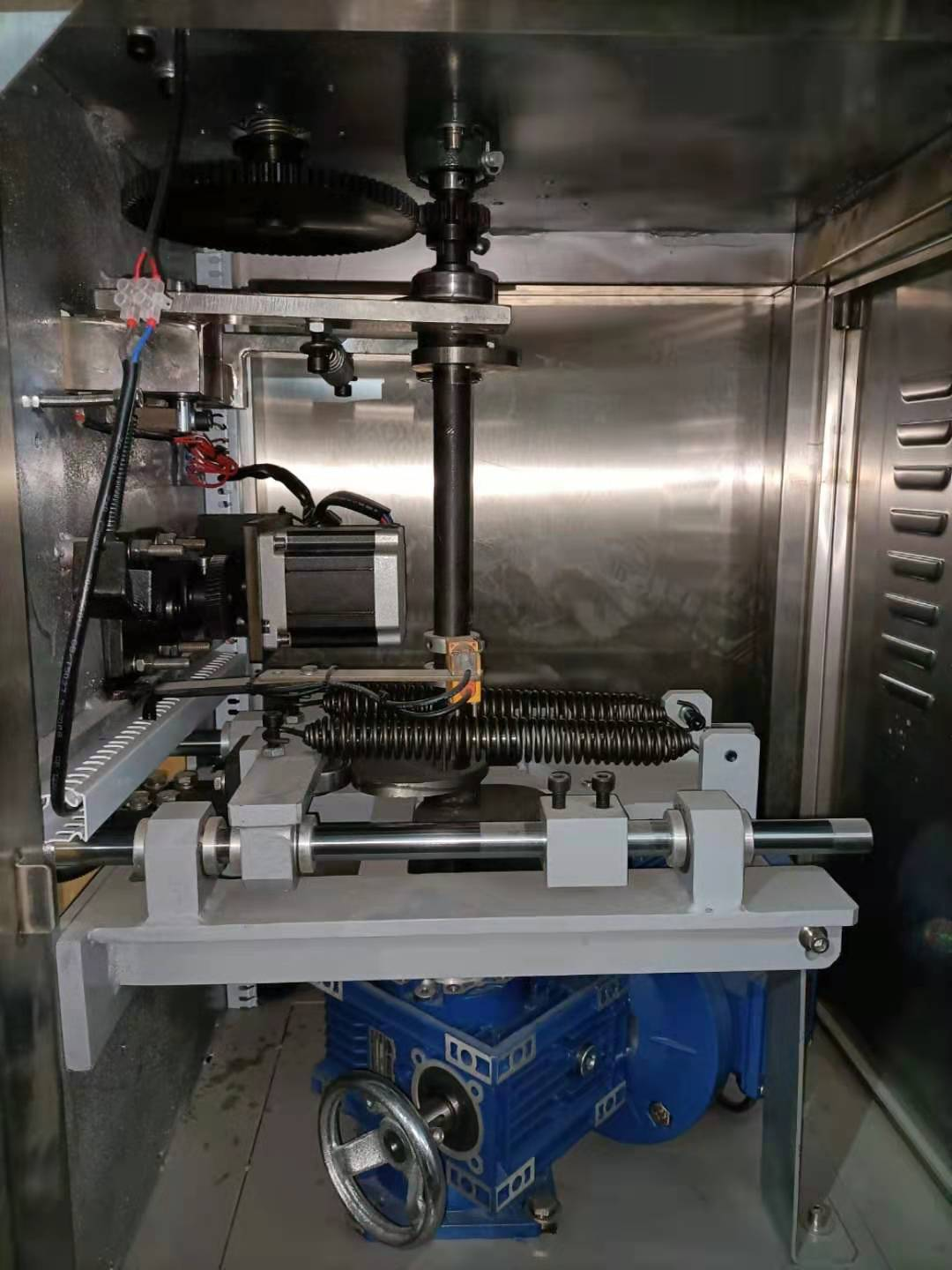

This equipment can directly use roll film forming back seal or middle seal bag, suitable for all kinds of particles or non-sticky fine particles, such as peanuts, nuts, puffed, melon seeds, sugar, salt, MSG, seasonings, etc.

From film release, date printing, color matching, molding, filling, sealing and bag cutting, the entire process can be completed continuously at one time.

Equipped with advanced PLC control system, touch screen settings, digital temperature control and safety emergency stop protection, etc.

The whole machine is made of stainless steel 304 material.

Technological process

Material Feeding | measuring cup | |||||

Film Feeding | Coding | coloring match | Forming | Filling | Sealing | Slitting |

1 | Control System | Siemens PLC |

2 | Touch Screen | WEINVIEW |

3 | Speed | 50-100 bag /minutes |

4 | Bag type | Back sealing or middle sealing |

5 | Bag length | 50-200mm |

6 | Bag width | 40-140mm |

7 | Sealing line | 5-10mm |

8 | Fill weight | 5-200g (optional) |

9 | weighing | Cup |

10 | Hopper | 50L |

11 | Hopper Shake | Standard |

12 | wheels adjustment control | Manual |

13 | Inner baffle | Include |

14 | Max film width | 320mm |

15 | Weight mold size | Up to buyer |

16 | Coding | Standard , colored tape |

17 | Photocell | Standard |

18 | Photocell (detecting materials) | Standard |

19 | Cutting | Tooth |

20 | Driver | MAechanical drive |

21 | Feeder Motor | 0.15Kw |

22 | Main Motor | 0.75Kw |

23 | Power | 220V 50Hz/60Hz |

24 | Weight | 260Kgs |

25 | Dimension | 900mm x 850mm x 1700mm |

26 | ||

Spare Parts | ||

1 | Toolbox | 1 cps |

2 | wrenches | 1 Set |

3 | heating pipes | 4 pcs |

4 | Extension spring 2 | 2pcs |

5 | Compression spring | 2pcs |

6 | Cutters | 2 pcs |

7 | Thermocouple | 2 pcs |

8 | Proximity switch | 1 pcs |

Usage

This equipment can directly use roll film forming back seal or middle seal bag, suitable for all kinds of particles or non-sticky fine particles, such as peanuts, nuts, puffed, melon seeds, sugar, salt, MSG, seasonings, etc.

From film release, date printing, color matching, molding, filling, sealing and bag cutting, the entire process can be completed continuously at one time.

Equipped with advanced PLC control system, touch screen settings, digital temperature control and safety emergency stop protection, etc.

The whole machine is made of stainless steel 304 material.

Technological process

Material Feeding | measuring cup | |||||

Film Feeding | Coding | coloring match | Forming | Filling | Sealing | Slitting |

1 | Control System | Siemens PLC |

2 | Touch Screen | WEINVIEW |

3 | Speed | 50-100 bag /minutes |

4 | Bag type | Back sealing or middle sealing |

5 | Bag length | 50-200mm |

6 | Bag width | 40-140mm |

7 | Sealing line | 5-10mm |

8 | Fill weight | 5-200g (optional) |

9 | weighing | Cup |

10 | Hopper | 50L |

11 | Hopper Shake | Standard |

12 | wheels adjustment control | Manual |

13 | Inner baffle | Include |

14 | Max film width | 320mm |

15 | Weight mold size | Up to buyer |

16 | Coding | Standard , colored tape |

17 | Photocell | Standard |

18 | Photocell (detecting materials) | Standard |

19 | Cutting | Tooth |

20 | Driver | MAechanical drive |

21 | Feeder Motor | 0.15Kw |

22 | Main Motor | 0.75Kw |

23 | Power | 220V 50Hz/60Hz |

24 | Weight | 260Kgs |

25 | Dimension | 900mm x 850mm x 1700mm |

26 | ||

Spare Parts | ||

1 | Toolbox | 1 cps |

2 | wrenches | 1 Set |

3 | heating pipes | 4 pcs |

4 | Extension spring 2 | 2pcs |

5 | Compression spring | 2pcs |

6 | Cutters | 2 pcs |

7 | Thermocouple | 2 pcs |

8 | Proximity switch | 1 pcs |