close

Choose Your Site

Global

| Availability: | |

|---|---|

| Quantity: | |

Rows | 4 Lines |

Article | ketchup |

Model | MW480Y-4 |

Size of bag | W 50mm L90mm |

Capacity (max) | 20-40bags/min/one line |

Control style | PLC control system + Chinese/English interface |

Case of machine | Stainless steel |

Sealing type | 4 sides sealing |

Air consumption | 0.8m⊃3;/min 0.8Mpa |

Power supply | 2.8KW/1N+PE/50HZ/AC220V |

Weight | 300kg |

Dimensions (mm) | 950*1470*2800mm |

Material of bag | Paper/polyethylene;cellophane/polyethylene;plated aluminum/polyethylene;BOPP/polyethylene;nylon/polyethylene |

Usage

This equipment can directly use roll film forming back seal or middle seal bag, suitable for all kinds of liquid , pasty fluid 。

From film release, date printing, color matching, molding, filling, sealing and bag cutting, the entire process can be completed continuously at one time.

Equipped with advanced PLC control system, touch screen settings, digital temperature control and safety emergency stop protection, etc.

The whole machine is made of stainless steel 304 material.

Applications:

It is suitable for packing liquid materials in the fields of food and medicine ,Such as Oral solution etc.

Characteristics:

1. PLC Control, English and large touch screen, Frequency step less bag length adjustable.

2. Easy operation, smooth performance, low noise, compact construction, convenient to maintenance, long life in use, small floor space in high packing speed and efficiency.

3. The case of machine is made of stainless steel S/S304.

4. Photoelectric tracking system for precise bag length and position of film.

5. Length of bag is easy to adjust on the interface without changing mould.

6. Digital temperature controller for vertical and horizontal sealing, intuitive and accurate.

7. Equipped with color ribbon printer.

8. Made according to the width of the bag, no wasting packing film.

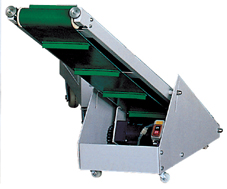

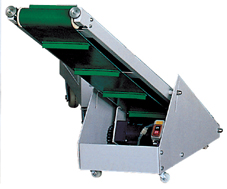

The machine can send the packed finished bag to after-package detecting device or packing platform.

v Feeding speed 30m\minute

v Dimension 2000×700×800mm

v Power: 45W, 220V

The main configuration

Name | Place of production |

Touch screen | Weinview/Taiwan |

PLC controller | MITSUBISHI/Japan |

Servo driver | Panasonic/Japan |

Transducer | AUTONICE/Korea |

Temperature control | Yudian/Xiamen |

DC power supply | MINWEI/Shanghai |

Solid-state relay | Fotek/Taiwan |

Intermediate relay | Tianzheng/Zhejiang |

Pneumatic component | Airtac/Taiwan |

Proximity switch | AUTONICE/Korea |

Machine Parts

5 lines Tahini packing machine (MW480Y-4) | 1set | Stainless steel 304 Piston pump metering method |

Finished products conveyor | Stainless steel | |

Automatic feeding pump | 1set | Stainless steel 304 |

Ribbon coding machine | 1set | |

Total | 4Sets |

Rows | 4 Lines |

Article | ketchup |

Model | MW480Y-4 |

Size of bag | W 50mm L90mm |

Capacity (max) | 20-40bags/min/one line |

Control style | PLC control system + Chinese/English interface |

Case of machine | Stainless steel |

Sealing type | 4 sides sealing |

Air consumption | 0.8m⊃3;/min 0.8Mpa |

Power supply | 2.8KW/1N+PE/50HZ/AC220V |

Weight | 300kg |

Dimensions (mm) | 950*1470*2800mm |

Material of bag | Paper/polyethylene;cellophane/polyethylene;plated aluminum/polyethylene;BOPP/polyethylene;nylon/polyethylene |

Usage

This equipment can directly use roll film forming back seal or middle seal bag, suitable for all kinds of liquid , pasty fluid 。

From film release, date printing, color matching, molding, filling, sealing and bag cutting, the entire process can be completed continuously at one time.

Equipped with advanced PLC control system, touch screen settings, digital temperature control and safety emergency stop protection, etc.

The whole machine is made of stainless steel 304 material.

Applications:

It is suitable for packing liquid materials in the fields of food and medicine ,Such as Oral solution etc.

Characteristics:

1. PLC Control, English and large touch screen, Frequency step less bag length adjustable.

2. Easy operation, smooth performance, low noise, compact construction, convenient to maintenance, long life in use, small floor space in high packing speed and efficiency.

3. The case of machine is made of stainless steel S/S304.

4. Photoelectric tracking system for precise bag length and position of film.

5. Length of bag is easy to adjust on the interface without changing mould.

6. Digital temperature controller for vertical and horizontal sealing, intuitive and accurate.

7. Equipped with color ribbon printer.

8. Made according to the width of the bag, no wasting packing film.

The machine can send the packed finished bag to after-package detecting device or packing platform.

v Feeding speed 30m\minute

v Dimension 2000×700×800mm

v Power: 45W, 220V

The main configuration

Name | Place of production |

Touch screen | Weinview/Taiwan |

PLC controller | MITSUBISHI/Japan |

Servo driver | Panasonic/Japan |

Transducer | AUTONICE/Korea |

Temperature control | Yudian/Xiamen |

DC power supply | MINWEI/Shanghai |

Solid-state relay | Fotek/Taiwan |

Intermediate relay | Tianzheng/Zhejiang |

Pneumatic component | Airtac/Taiwan |

Proximity switch | AUTONICE/Korea |

Machine Parts

5 lines Tahini packing machine (MW480Y-4) | 1set | Stainless steel 304 Piston pump metering method |

Finished products conveyor | Stainless steel | |

Automatic feeding pump | 1set | Stainless steel 304 |

Ribbon coding machine | 1set | |

Total | 4Sets |